The difference between offset and Korean bronzes:

1. Waste discharge. The use of offset bronzing process is an operation that does not need waste discharge, while Korean bronzing is good no matter what cutting plotter is used. The last step is to manually tear off the white part, so many customers feel that waste discharge is very troublesome.

2. Low production cost. First of all, offset bronzing belongs to mass production, starting with at least 500 bronzing pieces per day, so the cost of each piece of bronzing on average is naturally lower than that of Korean bronzing pieces. However, the cost of offset stamping equipment can be very high, and the price of large machines is at least 1 million or more.

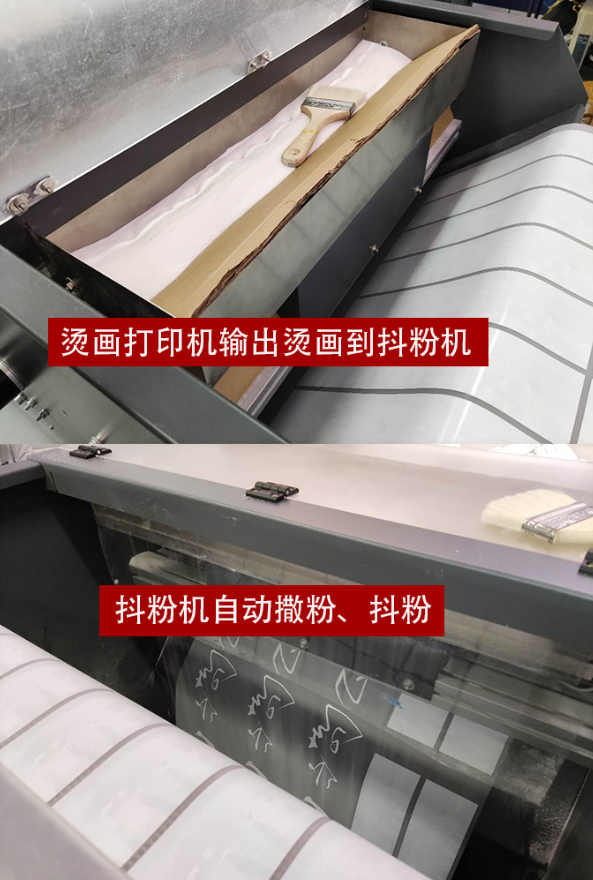

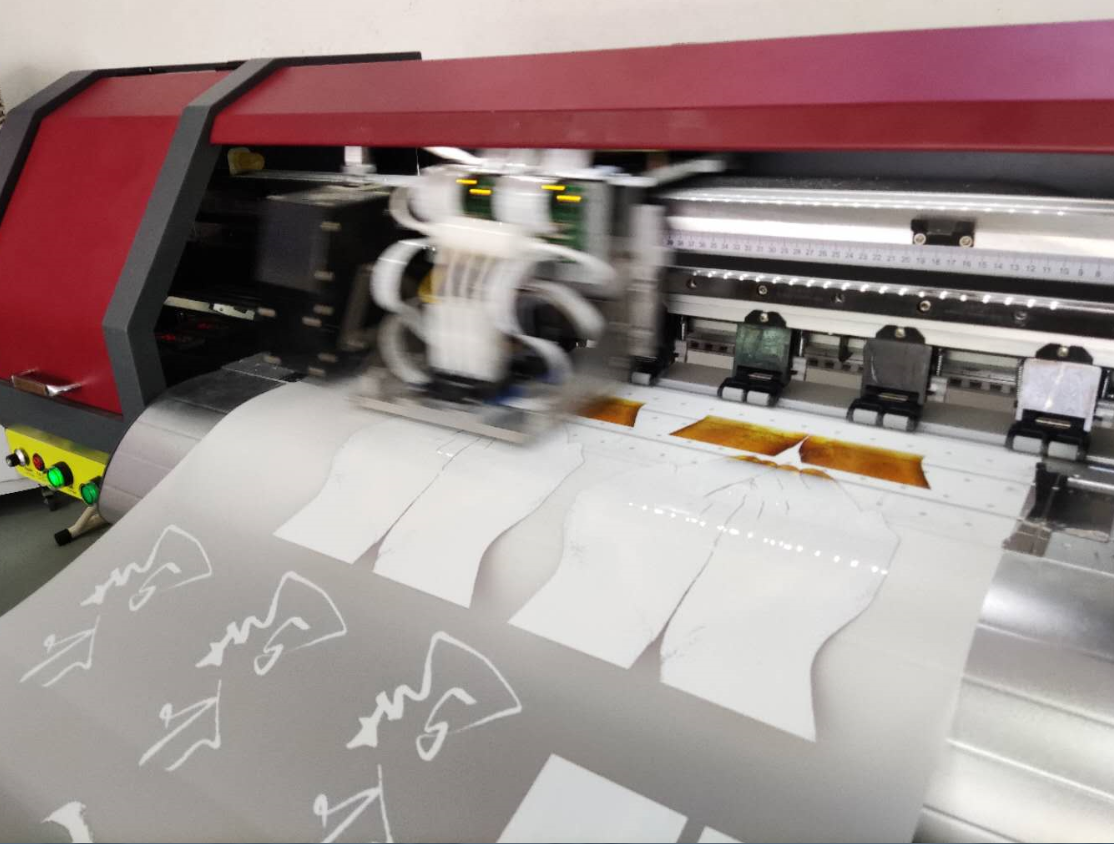

3, high efficiency. Because offbeat bronzing does not need to discharge waste, it is directly sprayed on the PET transfer film, so the production efficiency will be much higher than that of Korean bronzing, and basically dozens of bronzing will be produced by brushing.

Add: No.6-2, Jinhua Zhong Road,Zhongshan

Tel: 86-760-88667090

Fax: 86-760-88667096

E-mail: market2@titanjet.com.cn

betty@titanjet.com.cn

he@titanjet.com.cn